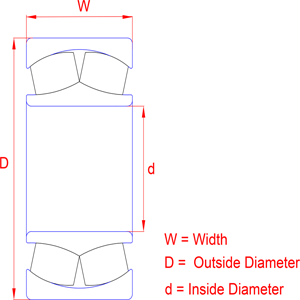

A spherical roller bearing is a type of rolling-element bearing that is designed to support heavy radial loads and axial loads in both directions. It derives its name from the spherical shape of the rollers and raceways. The primary components of a spherical roller bearing include an inner ring with two raceways, an outer ring with a spherical raceway, and spherical rollers. Here's a breakdown of the design and key features of a spherical roller bearing: 1. Inner and Outer Rings: The inner ring is typically mounted on a shaft and has two raceways, one on each side. The outer ring has a spherical-shaped raceway that allows the bearing to accommodate misalignment. 2. Rollers: Spherical roller bearings have barrel-shaped rollers. The shape enables the rollers to distribute loads evenly over a larger surface area. These rollers are usually symmetrical and self-aligning, allowing the bearing to tolerate misalignment and shaft deflections. 3. Cage: A cage is employed to keep the rollers evenly spaced and prevent them from coming into contact with each other. It also helps in guiding the rollers during operation. Common cage materials include steel, brass, or other suitable materials depending on the application requirements. 4. Symmetrical Design: The symmetrical design of spherical roller bearings allows them to carry heavy radial loads and moderate axial loads in both directions. This symmetrical design also facilitat/es self-alignment, making them suitable for applications where shaft misalignment may occur. 5. Seals and Lubrication: Spherical roller bearings can be designed with various sealing arrangements to prevent the ingress of contaminants and retain lubrication. Lubrication is crucial for smooth operation and increased service life. Bearings may be designed for grease or oil lubrication, depending on the application. 6. Clearance and Tolerance: Spherical roller bearings are available with different internal clearances and precision tolerances to meet specific application requirements. 7. Applications: Spherical roller bearings are commonly used in heavy-duty applications, such as mining, construction, paper mills, gear drives, and more, where high radial and axial loads are present. In summary, spherical roller bearings are designed to handle demanding conditions, provide self-alignment capabilities, and accommodate heavy loads. The design elements work together to ensure durability, reliability, and optimal performance in a variety of industrial applications. Wright definition and deign of Self Aligning Ball Bearing