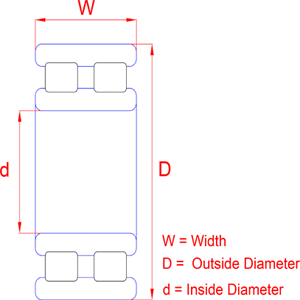

Cylindrical roller bearings are a type of rolling element bearing that supports high radial loads. The term "double row" in the context of cylindrical roller bearings refers to the arrangement of two rows of cylindrical rollers in the bearing assembly. Here's a more detailed breakdown of the components: 1. Cylindrical Rollers: These are the rolling elements of the bearing and are shaped like cylinders. The cylindrical shape allows these rollers to distribute loads evenly over a larger surface area, enabling them to handle both radial and axial loads. 2. Inner Ring:The inner ring is the part of the bearing that fits onto the rotating shaft. It provides a raceway for the cylindrical rollers. 3. Outer Ring: The outer ring is the stationary part of the bearing and provides a raceway for the cylindrical rollers. It may be integral or separate from the inner ring. 4. Double Row: In a double-row cylindrical roller bearing, there are two rows of cylindrical rollers arranged in parallel. This design increases the radial load-carrying capacity of the bearing and provides better axial load-carrying capability compared to a single-row design. 5. Cage: The cage is a component that separates and guides the cylindrical rollers, preventing them from coming into direct contact with each other. It maintains proper spacing and alignment of the rollers. The double-row configuration enhances the load-carrying capacity and rigidity of the bearing. It also provides some degree of axial load-carrying capability, making double-row cylindrical roller bearings suitable for applications where both radial and axial loads need to be accommodated. These bearings are commonly used in various industrial applications, such as machine tools, gearboxes, and rolling mills.

Types of Bearing

Cylindrical Roller Bearing Double-Row

© 2024 Engineer Data. All rights reserved. | Privacy Policy | Terms of Service

Engineer Data application provides a comprehensive suite of engineering calculations, including:

• Spur Gear Cutting Calculation on Milling Machine

• Helical Gear Cutting Calculation on Milling Machine

• Worm and Worm Gear Cutting Calculation on Milling Machine

• Gear Train Calculation for Helical Gear Cutting on Milling Machine

• Simple Indexing for Milling Machine

• Gear Train Calculation of Differential Indexing for Milling Machine

• Taper Calculation for Lathe Machine Jobs

• Hole Dividing Calculation for Drill Machine

• Bearing Number Identification and search of boundary dimension

Improve your engineering projects with accurate and reliable data. For more information visit Engineer Data

Engineer Data application provides a comprehensive suite of engineering calculations, including:

• Spur Gear Cutting Calculation on Milling Machine

• Helical Gear Cutting Calculation on Milling Machine

• Worm and Worm Gear Cutting Calculation on Milling Machine

• Gear Train Calculation for Helical Gear Cutting on Milling Machine

• Simple Indexing for Milling Machine

• Gear Train Calculation of Differential Indexing for Milling Machine

• Taper Calculation for Lathe Machine Jobs

• Hole Dividing Calculation for Drill Machine

• Bearing Number Identification and search of boundary dimension

Improve your engineering projects with accurate and reliable data. For more information visit Engineer Data